Email: info@jingwei.com.cn WeChat: +86 183 6827 5009

Your position:Home > News

Your position:Home > News

The digital cutting sector is increasingly adopting modular production systems. These systems enable production lines to be swiftly reconfigured based on product specifications, enhancing both flexibility and scalability in manufacturing operations.

The integration of digital cutting technology with smart manufacturing ecosystems allows for automated end-to-end processes, from design to production. This minimizes human intervention, thereby enhancing precision and consistency in output.

Augmented Reality (AR) technology is being utilized for the visual simulation of cutting paths and processes during the design phase. This improves accuracy and efficiency in production workflows, leading to better overall outcomes.

The development of control systems that can adapt to varying material properties and cutting conditions is providing refined and intelligent control over the production process. This adaptability leads to higher quality and more reliable production results.

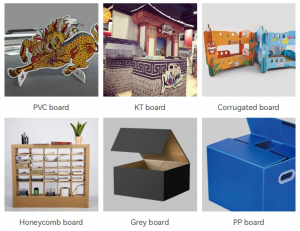

Digital cutting technologies are playing a crucial role in promoting a circular economy by optimizing material usage and minimizing waste. This not only supports sustainable growth within the industry but also aligns with global sustainability goals.

Please fill all the texts in the fields